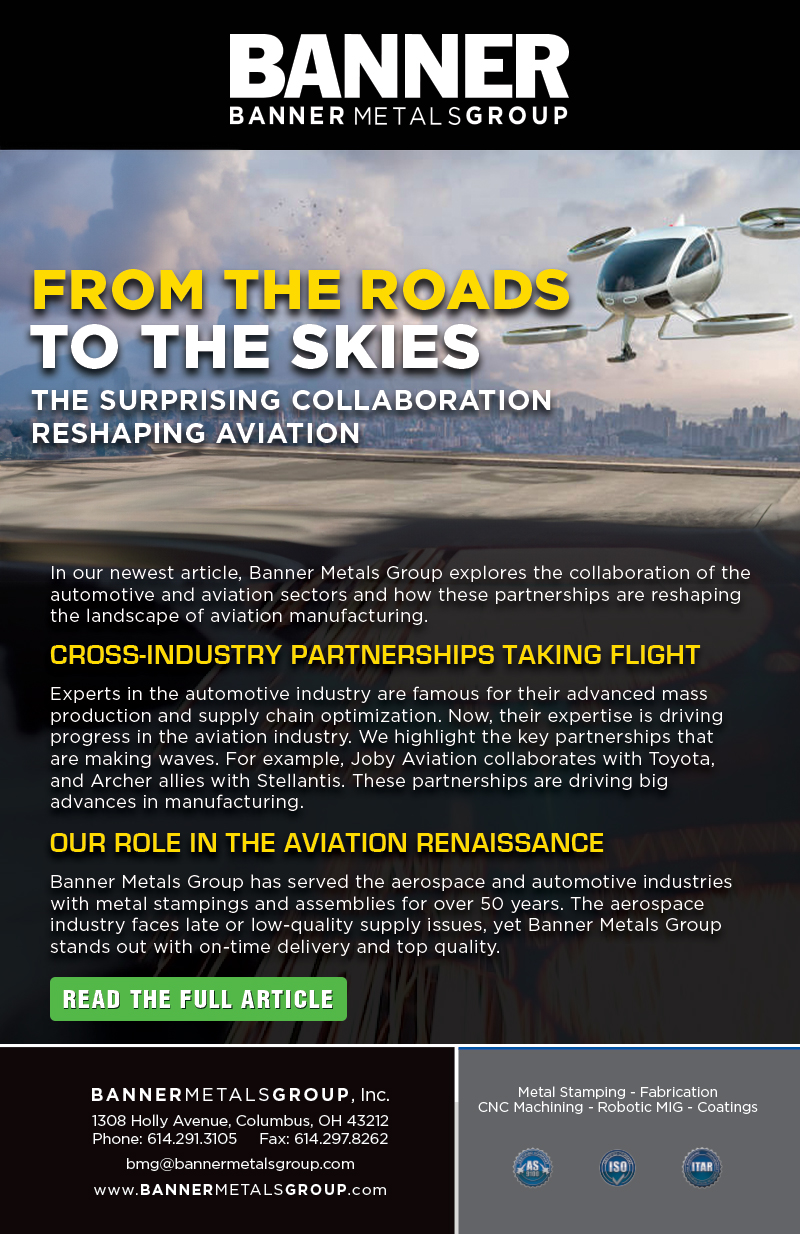

In our newest article, Banner Metals Group explores the collaboration of the automotive and aviation sectors and how these partnerships are reshaping the landscape of aviation manufacturing.

Cross-Industry Partnerships Taking Flight

Experts in the automotive industry are famous for their advanced mass production and supply chain optimization. Now, their expertise is driving progress in the aviation industry. We highlight the key partnerships that are making waves. For example, Joby Aviation collaborates with Toyota, and Archer allies with Stellantis. These partnerships are driving big advances in manufacturing.

Our Role in the Aviation Renaissance

Banner Metals Group has served the aerospace and automotive industries with metal stampings and assemblies for over 50 years. The aerospace industry faces late or low-quality supply issues, yet Banner Metals Group stands out with on-time delivery and top quality.

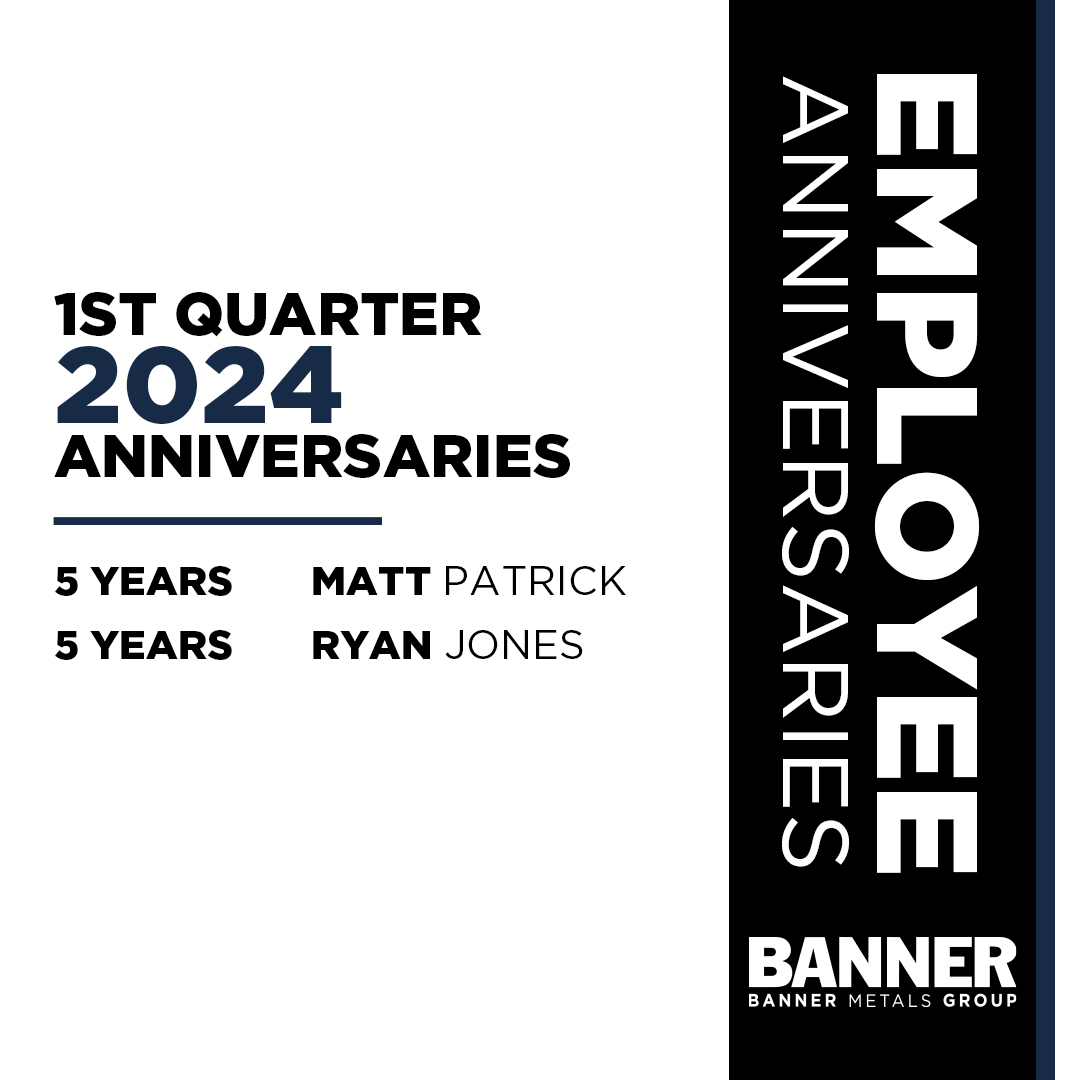

Today marks not one, but two important milestones at Banner Metals Group! Help us celebrate the 5-year work anniversaries of Matt Patrick and Ryan Jones!

Matt and Ryan have been integral parts of our team, bringing passion to everything they do. Their hard work and commitment have played a significant role in our growth and success over the years.

Cheers to more milestones!

During the holiday season we take time to reflect upon the good things we have, like our partnership with you.

It's also the perfect time to express gratitude through giving. A donation has been made to Mid-Ohio Food Collective and Ronald McDonald House.

May the peace, love, and joy of the season be with you and yours this holiday and throughout the coming year.

Choosing a metal stamping partner affects not just the quality of your products but also the efficiency of your operations and your business's bottom line. This excerpt from the article introduces six crucial factors to consider while selecting a metal stamping company, ensuring you gain a competitive edge.

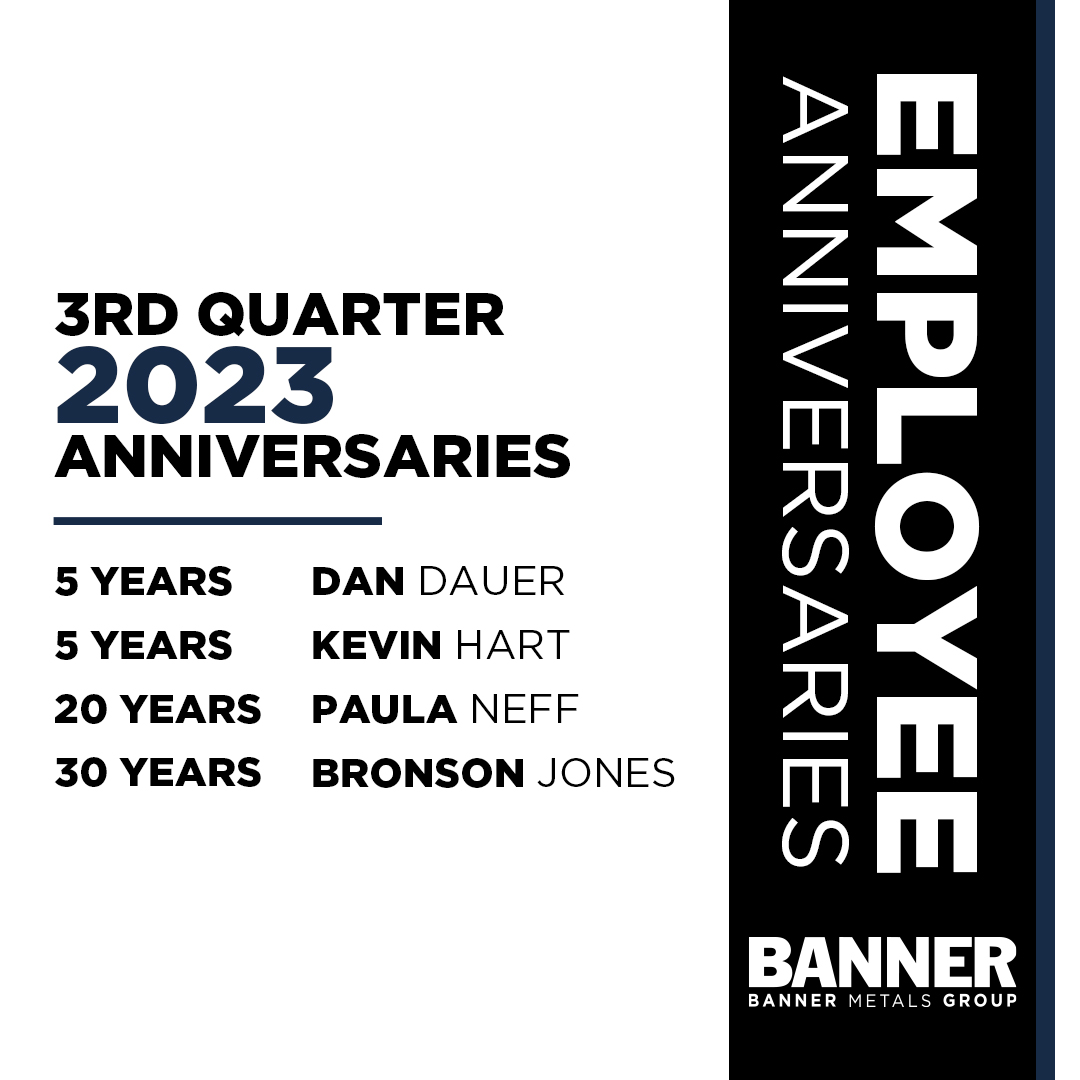

Congratulations and cheers to the outstanding members of our team who are marking work anniversaries during the third quarter. Your dedication and commitment are crucial to our success, and we're honored to have you as part of the Banner Metals Group family.

Let's recognize these individuals and their milestones:

Each has played an essential role in our company, and their hard work continues to inspire us all. Here's to the achievements of the past and the milestones yet to come!

Our team and their families enjoyed a day of laughter, adventure, and cherished moments. We're grateful to the organizers for their hard work, making it a resounding success!

We value teamwork and fostering a positive company culture at Banner Metals Group. This picnic was a joyful reminder of the strong bonds within our team. Cheers to more celebrations and memorable experiences ahead!

At Banner Metals Group, our people and processes are vital in delivering exceptional products and conducting business with integrity. Our unwavering commitment to our core values ensures utmost customer satisfaction, and we take great pride in what we call – The Banner Difference.

We are thrilled to announce the launch of our brand-new website, designed to showcase the diverse industries we support and the comprehensive range of services we provide. However, our website goes beyond just a display of our offerings. It delves into the why and how behind everything we do. It sheds light on what makes Banner Metals Group a great workplace and a reliable source of high-quality metal products delivered on time and cost-effectively.

On our website, you'll have the opportunity to explore the distinct aspects of The Banner Difference and understand why we stand out in the industry. Discover the thorough attention to detail in our processes, the passion that drives our talented team, and the unwavering dedication to customer satisfaction that underpins every aspect of our business.

We invite you to visit our new website to learn more about what makes us different and how trust, quality, and reliability shape our approach.

For 100 years, Banner Metals Group has been a prominent player in American manufacturing. Founded in 1921, the company remains true to its core values of quality, honesty, and reliability – and also changing and adapting to meet each day’s evolving demands.

Starting off as a full-service metal stamping business called the Banner Die, Tool & Stamping Company, Banner has grown into a complete metal products group. Back in 1999, it was renamed Banner Stamping Company. And just over a decade later, in 2011, it was renamed again as Banner Metals Group, a name better representing the many services it provides.

With industry expertise covering aerospace, automotive, commercial truck and off-highway, and lawn and garden, the Ohio-based business is known for its ability to adapt to changes in the technologically fastest-evolving marketplaces.

Banner Metals Group was honored to receive 100th Anniversary recognition by the Ohio House of Representatives and the Columbus Chamber of Commerce. Assistant Minority Leader Kristin Boggs, Ohio House of Representatives - District 18, presented a commendation celebrating this prestigious milestone. Don DePerro, President & CEO of The Columbus Chamber of Commerce offered congratulations and gratitude to Banner for a century of contributions to Columbus and the surrounding area.

Pictured: (L to R) C. Bronson Jones, President & CEO, Banner Metals Group, Representative Kristin Boggs, Don DePerro

Milestone Manufacturers: 100 Years and Counting

These 10 U.S.-based manufacturing firms have achieved the century mark, joining a select group of long-lasting colleagues.

- Jill Jusko

U.S. manufacturing continues to demonstrate its long-haul capabilities, and IndustryWeek continues to salute their achievements.

Welcome to another in our continuing series of galleries showcasing U.S. manufacturing companies that have reached their 100th birthday. It's no small achievement, and it's deserving of recognition.

These 10 manufacturing companies in this gallery appear in alphabetical order. The name of each company is linked to the history page on their website whenever possible, providing you with access to more historical detail than we can share in this presentation.

On behalf of the members of the Senate of the 134th General Assembly of Ohio, we are pleased to commend Banner Metals Group as it celebrates the One Hundredth Anniversary of its founding.

Since its establishment in 1921 as Banner Die, Tool, and Stamping Company, the Banner Metals leader in the production of complete metal products. This fine enterprise has continually demonstrated its exemplary commitment to the highest standards of service, quality workmanship, and competitive pricing, and its dedication to the best interests of the customer has been evident in all its transactions.

The noteworthy success of Banner Metals Group is attributable largely to the loyal service of its highly qualified and committed staff, as well as to the innovation and foresight of its management. Their combined efforts have earned the venture a well-deserved reputation for excellence and have distinguished the organization as a worthy business that has contributed greatly to the area's economic well-being.

Thus, with sincere satisfaction, we extend special recognition to Banner Metals Group on its One Hundredth Anniversary and extend best wishes for the future.

Banner Metals Group is a complete metal products group, providing metal stamping, fabrication, welding, CNC machining, laser cutting, and complete engineering services for aerospace and other demanding industries throughout the world.

Central Ohio-based metal products and engineering services company honors 100 years of collaborative partnerships with clients in safety-critical industries

COLUMBUS, OH, February 1— Banner Metals Group, a worldwide provider of metalworking machinery services, is celebrating 100 consecutive years in business as a leader in metal stamping and metal products.

The Banner Die, Tool and Stamping Company began providing full-service metal stampings in the heart of Ohio in 1921. Since then, Banner Metals Group has evolved into a recognized global leader in complete metal products for a wide variety of industries, including aerospace, automotive, commercial truck and off-highway, and lawn and garden.

Over a 100-year span Banner endured the depression, provided critical manufacturing support to the U.S. military during WW II, and stood strong after the attacks of 9/11. That same resilience is evident today during the COVID-19 pandemic.

Banner has become a supplier of choice because of a commitment to protect their customers' brands through meeting and exceeding expectations. Since its initial founding, Banner has always made quality a top priority, as evidenced by ISO 9000 and AS9100D certifications – two distinctions of excellence for standardization and quality assurance.

For C. Bronson Jones, President and CEO, Banner's 100-year heritage is a product of its trusted people, quality products and unwavering commitment to company Vision, Mission and Values.

"Providing our customers with the highest quality parts possible is our priority," he said. "Every one of our employees understands the impact our products have, and the standards that are expected. Our valued employees are the key to our continued success".

Banner has established a century-long legacy that the world has come to trust. This centennial celebration is a testament to Banner's ability to remain an authority in the ever-changing metal forming industry. For more information on Banner Metals, visit bannermetalsgroup.com.

Banner Metals Group is a complete metal products group, providing metal stamping, fabrication, welding, CNC machining, laser cutting, and complete engineering services for aerospace and other demanding industries throughout the world.

Banner Metals Group is a key part of the automotive supply chain. We produce high volume stampings and welded assemblies for the automotive industry. That includes providing parts used in automobile chassis, brake and exhaust systems, and seatbelt assemblies – made to meet the exacting standards of top auto manufacturers.

Banner recognizes that changes in government mandates and customer expectations require quick changeover practices. As parts change in size and weight, you can count on our processes to ensure the right parts are where you need them, when you need them. You can also rely on Banner to understand your operational, safety and regulatory requirements.

Our experience in the automotive industry began in 1971 - therefore we have extensive experience making parts for Tier 1 and Tier 2 automotive companies. You can count on Banner for your entire automobile and commercial automotive needs. Our adherence to Six Sigma and Lean Principles is very important to all industries, especially automotive where precision components need to be verifiably high quality.

Have an automotive project or question? Banner Metals Group welcomes the opportunity to evaluate your project to provide a recommendation regarding materials, design, engineering, and manufacturing. Please contact us to review your project's requirements.

In the aerospace industry, there is no place for metal components that do not meet the very highest standards of quality. Flight crews and passengers depend on the integrity, reliability and safety of metal parts that go into a plane. With over seventy years of experience servicing this demanding industry, it's not uncommon for others to turn to us for evaluation of an aerospace part they are having difficulty with – especially parts that are made off-shore.

In this particular case study, we used Value Analysis/Value Engineering (VA/VE) as one of our most important tools to systemically analyze existing parts. VA/VE helps us to identify substitute materials and methods with less expensive alternatives, without sacrificing quality or functionality. VA/VE focuses entirely on the functional aspects of components and materials, and not their physical characteristics. VA/VE was successfully employed to overhaul the production process of this aerospace part, which exceeded all specifications for surface flatness while greatly reducing scrap.

CASE STUDY

Application: Aerospace

Part Description: Aircraft Seat Backrest (for flight attendants)

The Banner Quality Clinic is an on-site emergency clinic for metal part analysis and corrective action.

Modeled after a hospital emergency room, this quality clinic has an extensive process to verifiably resolve any issue with a nonconforming part.

This clinic performs several key functions:

Banner Metals Group operates under Six Sigma and Lean principles and continuously updates quality practices to ensure industry compliance, with complete traceability.

"As a supplier to aerospace and automotive industries, we know that flight crews and passengers rely on the quality of our parts. Because of this, we address quality with unwavering diligence and are proud to introduce this emergency clinic approach to the manufacturing industry," said Bronson Jones, President/CEO, Banner Metals Group.

Banner Metals Group believes in living into our Vision, Mission and Values. For nearly 100 years we have partnered with various charities and events in our Community and are proud to be a longtime sponsor of the Grandview Heights Parks & Recreation Great Pumpkin Run.

On Saturday, October 26th hundreds of runners and walkers alike donned their raincoats and braved the cold temperatures for the 41st annual run. The event kicked off with the Tiny Tots race – with over 80 kids ages 6 and under participating this year!

The 5K turnout was fantastic despite the weather.

Team Banner was comprised of Rahul Chanana, Christina Dearwester, Elizabeth Treon and Todd and Carson Mitch. Jenni Moeller and Paula Neff opted for dry land and volunteered at the Banner sponsor table.

Photo credit: Marta Durban, Recreation Supervisor, Grandview Heights Parks & Recreation and Jeff Coudron, Speedy-Feet Official Timing (featured top left).

Value Analysis Leads to Better Aircraft Seat Production at Less Cost

Bronson Jones

President & CEO

Banner Metals Group

In the aerospace industry, there is no place for metal components that do not meet the very highest standards of quality. Flight crews and passengers depend on the integrity, reliability and safety of metal parts that go into a plane. With over seventy years of experience servicing this demanding industry, it's not uncommon for others to turn to us for evaluation of an aerospace part they are having difficulty with – especially parts that are made off-shore.

Our unwavering commitment to understanding and meeting customer needs is the Banner Difference.

The aerospace industry demands extremely stringent quality measures like no other. Additionally, they also demand on-time delivery along with cost cutting measures. Therefore, a successful supplier of aerospace parts must look for every opportunity to increase value and reduce lead time while maintaining the required high level of quality.

Value Analysis/Value Engineering (VA/VE) is one of the most important tools for hitting those seemingly contradictory goals of high quality, but also high value and low lead times. VA/VE is the process of conducting a systematic analysis to identify the best value possibilities for design, materials, and processes. VA/VE attempts to substitute materials and methods with less expensive alternatives without sacrificing quality or functionality. VA/VE focuses entirely on the functional aspects of components and materials, and not their physical characteristics.

In our Aerospace Case Study we discuss how VA/VE was employed to overhaul the production process of an aerospace part to produce a higher quality part, faster, and at less cost.

As an international company, Banner Metals Group understands the importance of a strong Business Continuity Management System. We know that identifying potential threats upfront gives us the best opportunity to provide an effective response to safeguard the interests of our customers and suppliers.

Our comprehensive Business Continuity Management Systems integrates the disciplines of Emergency Response, Crisis Management, Disaster Recovery, IT Continuity, Business Continuity, Societal Security, Quality Management Systems, Legal & Regulatory, Awareness & Communication, and Business Impact & Risk Assessment.

Our BCMS is assurance to our customers and suppliers that we will protect their brands from a variety of risks and to deliver as promised your high quality parts to keep your production up and running.

Value Analysis Leads to Cost Savings for Aerospace Industries

Bronson Jones

President & CEO

Banner Metals Group

Forecasts are predicting strong growth in the commercial and defense aerospace industries during the coming year, driven by increased demand for passenger travel and increased defense spending globally. In the commercial sector, there was a record high backlog of aircraft unit production at the end of 2017. However, the aerospace industry demands extremely stringent quality measures regardless of growth rate.

There are many suppliers capable of meeting these quality level demands, so how can one producer stand out? A successful supplier of aerospace parts must look for every opportunity to increase value and reduce lead time while maintaining the required high level of quality.

Manufacturing Tomorrow is a podcast series brought to you by the Ohio Manufacturing Institute at The Ohio State University.

Guest Spotlight

Bronson Jones, Banner Metals Group

Bronson Jones is CEO and owner of Banner Metals Group in Grandview, Ohio. Founded in 1921 as a tool and die company, Banner Metals Group has expanded its offerings to metal stamping, fabrication, welding, CNC machining, laser cutting, and engineering services. Banner Metals manufactures metal products for industries throughout the world, including aerospace and automotive.

Bronson took the helm of this family-owned company four years ago, after serving as vice president and general manager for 20 years. Before Banner Metals, he worked at McDonnell Douglas; early on in his career, he was a tool and die maker for Superior Die Tool & Machine Company.

We are proud to serve many industries where safety is of the utmost importance. Those industries rely on the dependability of critical parts manufactured by Banner Metals Group. This will change everything you know about metal stamping

Banner is one of the first metal stamping companies to have achieved this quality management system certification.

WHY THIS MATTERS

Achieving this level of certification means our customers are ensured that they are purchasing the highest quality parts made from the best materials and processes.

This certification supports our mission to:

While AS9100D is the standard for the manufacturing of parts, components and assemblies for the aerospace and defense industries – all industries will benefit from this advanced quality management system certification.

Message From: C. Bronson Jones, Banner President

About a year ago, I was asked, "So now that the Company is under new leadership, where do you want to go and what do you envision it to be?"

With that question, I began a quest to establish the vision of our Company, our mission, and our core values.

This process was given careful consideration and thought by our Leadership team.

These statements are not meant to be placed on a wall and forgotten. They are meant to express the standards of how our Company will operate and inspire every associate to fulfil the role of a Leader both at work and in their daily lives.

Vision, Mission and Values are components of a Leadership System that will eventually be created by everyone. That system will guide all aspects of our business. The Leadership System will be used during interviews of potential candidates who want to be part of our Leadership team, be the foundation of performance reviews, and considered when making all strategic decisions, to name a few.

Banner Metals Group will continually strive to become the Company of choice for manufacturing metal products.

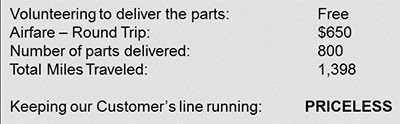

Early one Wednesday morning in January, Banner received an emergency phone call: due to an inventory error, one of our customers was about to run out of parts resulting in the shutdown of an entire assembly line. Banner immediately held an emergency production meeting to try to determine a course of action.

Two hours later Production Manager Joe Smith boarded a plane, flew approximately 700 miles one way and hand delivered enough parts to keep the line running until a full shipment could be delivered the following day.