Navigating the intricacies of the metal stamping industry can be daunting, especially when the quality of your products and the efficiency of your operations hang in the balance. Are you in the manufacturing sector and facing the challenge of choosing the perfect metal stamping partner? By delving into this guide, you're taking the first step towards making an informed decision that sidesteps common pitfalls. Our extensive experience in the industry offers you a unique vantage point filled with actionable tips and questions for assessing your metal stamping partner, so you make the right choice. Equip yourself with the knowledge to ensure a metal stamping company aligns with your ambitions and expectations.

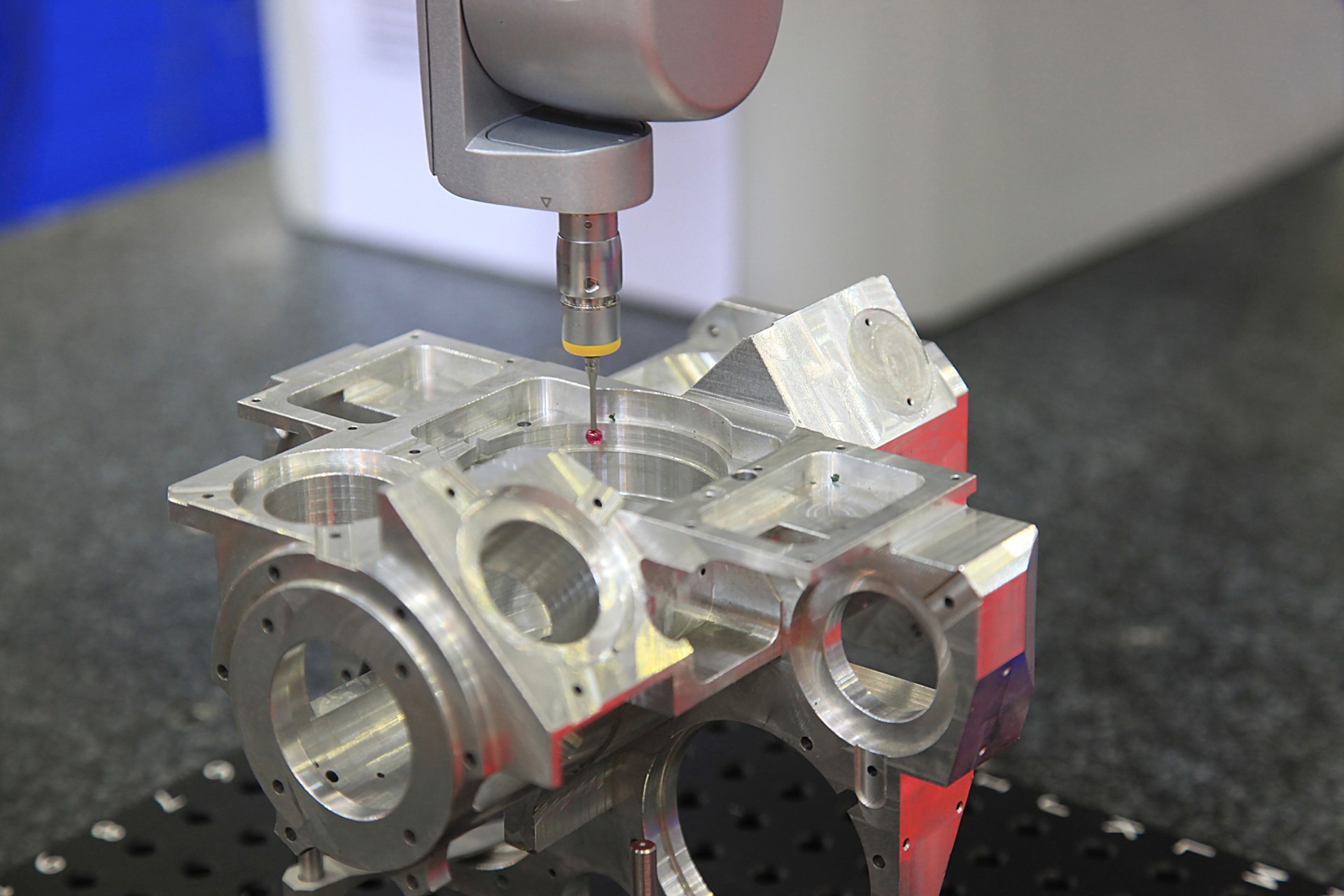

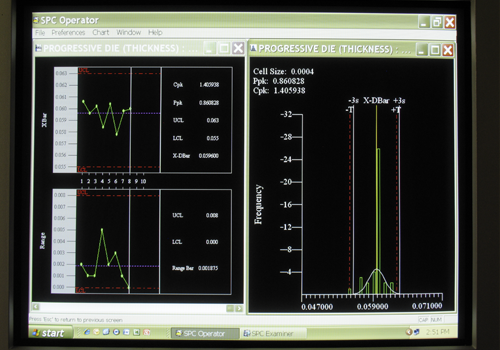

Quality is the cornerstone of any reputable metal stamping company. To ensure superior results, inquire about the type of Quality Management System (QMS) they have in place. A robust QMS is crucial, from part design to packaging, enveloping every stage. Ask if they use advanced technology such as electronic data collection, sensors, and automation to monitor and maintain consistent quality standards.

You will want to understand what the company measures to gauge quality. Inquire about their rolling 12-month internal and external Parts per Million (PPM) figures. Also, find out who is responsible for quality control within the organization. Do they have dedicated inspectors, trained operators, or a customer-driven approach?

A top-notch metal stamping company will showcase their commitment to quality throughout their production facility. Look for signs of organization, attention to detail, and dedicated spaces like a Quality Lab or Quality Clinic. Furthermore, inquire if they have processes to ensure your specific quality requirements are effectively communicated to their suppliers.

On-time delivery is necessary for maintaining a smooth and efficient manufacturing process. Understand their definition of on-time delivery – does a partial shipment count, or is 100% fulfillment mandatory?

A reliable company will benchmark their delivery performance within the industry to ensure competitiveness. They should monitor their suppliers' delivery performance, holding them to the same high standards. Ask if the company has established performance targets for its internal processes and suppliers. Equally important, determine if they take prompt action when targets are unmet.

For a comprehensive understanding of their delivery reliability, ask about their rolling 12-month on-time delivery performance. This will give you insight into their ability to meet deadlines consistently.

Safety is a top priority in any manufacturing environment, and a responsible metal stamping company should care about the well-being of their employees. Inquire about their safety monitoring practices and the specific aspects they monitor to ensure a safe workplace.

Ask if employees have a working knowledge of health and safety topics and if opportunities for improvement are proactively identified and resolved. Regular communication on health and safety throughout the facility is necessary for maintaining awareness and fostering a safe culture. Ensure employees actively participate in Environmental, Health, and Safety (EH&S) initiatives.

A strong safety culture is characterized by an environment where employees feel comfortable reporting safety concerns. Ask if the company encourages open reporting and if they conduct regular audits of their health and safety program by an external party. This demonstrates their commitment to maintaining a safe work environment.

Capacity isn't just about meeting today's needs; it's about scaling for tomorrow. Determine their open capacity to take on new business. Are they willing to invest in additional resources, such as personnel, equipment, or facility expansion, to accommodate your requirements?

Ask if they have identified key equipment and implemented a predictive maintenance schedule to minimize downtime. The ability to respond quickly to emergency orders or rapid increases in demand is crucial for seamless operations. Do they have the necessary capacity and agility to meet such needs?

Reliable communication is a cornerstone of trust in business-to-business dealings. Inquire if they are available to take calls 24/7/365, as urgent matters can arise at any time. Ask for a current list of contacts and the various methods by which you can reach them.

Consider the years of service and turnover rates for key contacts within the company. A low turnover rate signifies stability and expertise, ensuring consistent and reliable service. Find out if they communicate in your preferred timeframe, be it in minutes, hours, days, or weeks.

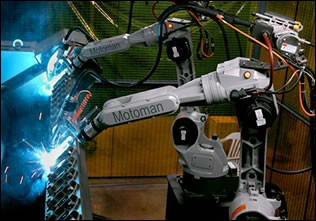

A metal stamping company that provides a wide range of services internally and externally can offer a comprehensive solution for your manufacturing needs. Ask about the services they provide internally, ensuring they can handle all aspects of your project. Check if they have long-term partnerships with outside processors. This ensures seamless integration and coordination between different stages of the manufacturing process. If they don't have a particular service internally, ask if they can leverage external partnerships to meet your requirements.

To stay ahead of the curve, a forward-thinking metal stamping company will be up to date with the latest technology for internal and external processes. Ask if they actively seek and implement new advancements, as this demonstrates their commitment to innovation and delivering cutting-edge solutions.

Finalizing your choice of a metal stamping partner is more than just ticking off a checklist; it's about securing your manufacturing future. At Banner Metals Group, we don't just meet industry standards; we aim to redefine them. Let's collaborate, and you'll see how our dedication to these crucial pillars sets us apart, offering unparalleled value and innovation in the metal stamping arena. We look forward to meeting and exceeding your expectations, delivering outstanding results and exceptional customer service for all your metal stamping needs.